As the global demand for renewable energy grows, biomass boiler power systems are emerging as one of the most efficient and eco-friendly solutions. By using agricultural and forestry residues as fuel, these systems generate electricity efficiently while reducing carbon emissions and supporting sustainability goals.

For larger-scale projects, a biomass boiler power plant integrates multiple systems to provide industrial or grid-connected power. This article explains how a biomass boiler power system works, its components, advantages, and why it’s an ideal investment for companies seeking green energy solutions.

A biomass boiler power system is an integrated setup that uses organic biomass fuel—such as wood chips, rice husks, or palm shells—to produce clean electricity.

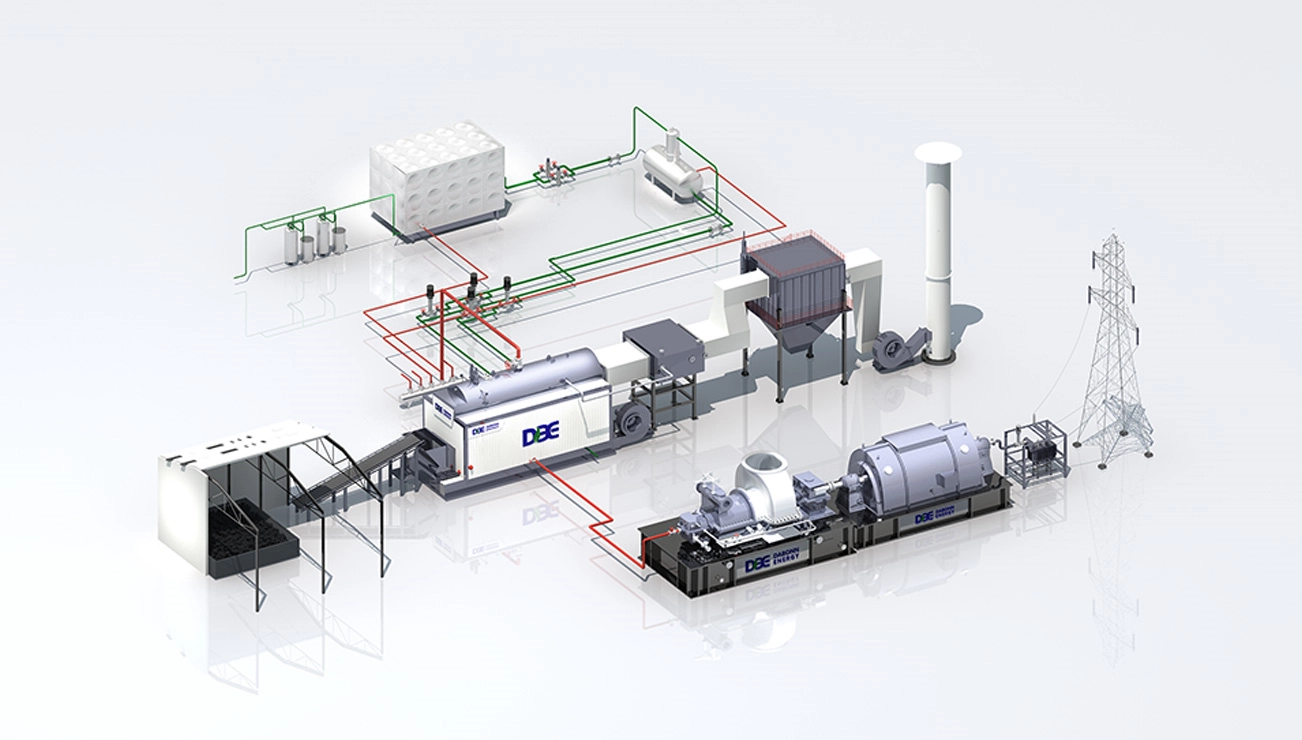

The biomass boiler burns these fuels to create high-pressure steam, which drives a steam turbine connected to a generator. The produced electricity can be used on-site or exported to the grid.

In larger projects, a complete biomass boiler power plant combines several biomass boiler power systems to achieve higher capacity and stable energy output.

The boiler is the heart of the biomass boiler power system. It burns biomass fuel to produce heat, converting water into high-pressure steam.

Common types include:

The turbine converts steam energy into mechanical motion to drive the generator.

The generator converts mechanical energy from the turbine into electrical energy. Together, these components form a continuous, efficient, and eco-friendly biomass boiler power system.

For larger industrial applications, a biomass boiler power plant may include multiple systems working in parallel to provide higher capacity and reliability.

Biomass is part of the natural carbon cycle. CO₂ released during combustion equals the amount absorbed during plant growth, making it nearly carbon-neutral.

A biomass boiler power system converts agricultural and forestry residues into electricity, reducing landfill waste and environmental pollution.

Unlike wind or solar, biomass energy is not weather-dependent, ensuring continuous electricity supply.

Many countries support biomass power plants with feed-in tariffs, tax benefits, and carbon credit programs, improving ROI.

Biomass fuels like rice husk and wood pellets are affordable and widely available, reducing operational costs compared with fossil fuels.

Besides reducing emissions, biomass boiler power systems create jobs, boost rural income, and support sustainable growth.

A biomass boiler power system can utilize various renewable fuels:

Fuel flexibility allows systems to adapt to locally available resources and reduce operating costs. In larger biomass boiler power plants, multiple fuel types can be combined for continuous operation.

In Southeast Asia, a 15MW biomass boiler power system fueled by rice husk shows excellent performance. It uses a circulating fluidized bed boiler and a condensing steam turbine, processing over 200 tons of rice husk daily.

The system supplies electricity to over 20,000 households and reduces more than 60,000 tons of CO₂ annually. This example demonstrates how a biomass boiler power plant can combine multiple systems for large-scale, profitable, and eco-friendly energy production.

We provide customized biomass boiler power systems for industrial, agricultural, and utility-scale applications.

Our advantages:

Whether you need a small biomass heating system or a large biomass boiler power plant, we deliver tailored solutions for your energy and sustainability goals.

A biomass boiler power system is a sustainable and cost-effective solution for clean energy generation. By turning agricultural waste into electricity, it reduces carbon emissions, creates local jobs, and ensures stable energy supply.

For larger industrial projects, integrating multiple biomass boiler power systems forms a complete biomass boiler power plant, providing scalable, eco-friendly, and profitable energy solutions.

Contact us today to learn how our biomass boiler power systems can deliver renewable energy for your business. Whatsapp: +8613838529852

Get Free Solution

We provide medium and long-term solutions to the problems of biomass waste, transforming waste into energy at no environmental cost and making it economically viable and at the same time compatible with the international environmental regulations and standards

Get More Product Information For Free